What are the different types of valve actuators?

What are the different types of valve actuators?

Initially, people used to control valve opening and closing manually, but now they can buy actuation equipment to manage the opening and closing. Different actuators are available in the market; you can invest in them based on your requirements.

The actuator consists of a box with an input and output mechanism. This mechanism is used to manage the opening and closing of the valve.

An actuator is also used to convert energy to achieve physical movement. For example, it is used to convert energies like hydraulic or electrical energies into mechanical force so that it can help in initiating movement. Many experts compare it with human body movement and state that it is essential machinery in the modern world even though it is not discussed often in modern-day technology debates.

If you want to know about the different types of actuation equipment, then you can refer to the following points:

Pneumatic actuator (Quarter turn)

These types of actuation machines are quite popular for their versatile functions as they can when there is not enough electrical power available for your valve operation. This small machinery can handle a big valve by providing few-inch pounds of torque and millions of inch-pounds to the small valves. It also has cylindrical machinery that converts the linear action into a quarter-turn action. You can depend on this machine, especially in emergencies, because it has an extra spring that shuts down in sudden power cuts.

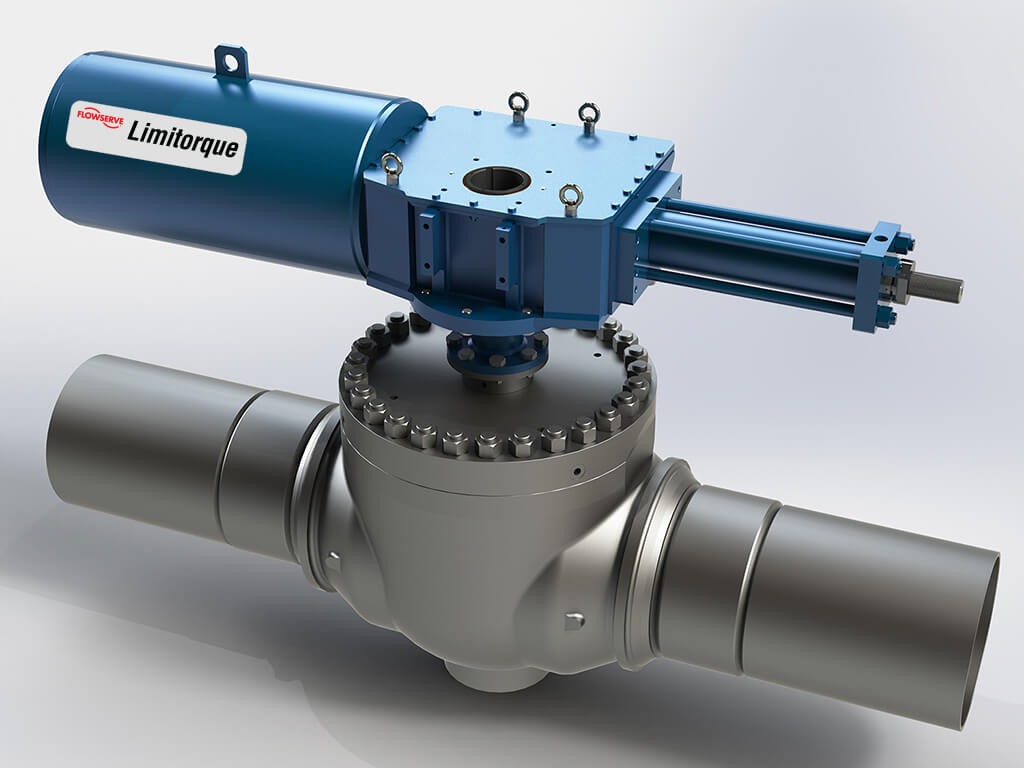

Electric actuator (multi-turn)

Among all the types of actuators available in the market, the electric ones are the most popular because of their commendable dependency. This machine comes in different motors, from single to three-phase motors, so that you can use it on the big valves. In addition, it has a multi-turn function, which allows it to gear, spur the valve, and open and close it.

Electric actuator (Quarter turn)

An electric actuator comes in two types, one with the multi-turn function and the other with a quarter-turn function. The major difference is that the quarter turn actuator provides the value with a 90-degree turn. These machines are best for small valves because they can not function with large valves. It is because of their low power requirements. So if you require an actuator to use small valves, you can buy the one with a quarter-turn function.

Manual actuator

You can also invest in a manual actuator, as these machines come with manual functions like chain wheel, handwheel, lever, and many other operations to use these features on your valves. However, you can use this machine only on some selected valves because most of the valves work well with electric actuators.

According to experts, it is better to use electric or pneumatic actuation tools to work on your valves because they are comparatively safe, especially when your valve is massive and located in an inaccessible spot. It will not only be safe but will also allow you to have more control over the whole system to control the results. In addition, some valves are impossible to open, close, or turn with manual power; hence it is essential to use the ones with external power.

These points list all the different actuation tools available in the market. You can find the best sellers online and check their inventory to select an actuator of your preference. Make sure you know the size and specifications of the actuator you need so that you can buy it accordingly. It will make your job easy.

Lucas Noah, with a Bachelor of Information Technology (BIT) degree, is a prolific writer known for his expertise in the tech world. Currently, he brings his wealth of knowledge to Creative Outrank LLC and Oceana Express LLC, enriching their websites with hi... Read more